Future-ready packaging. Live at the K Show.

Experience next-gen technology for smart packaging, medical solutions, appliances – live at the Kiefel booth

Discover how we turn passion into powerful technologies: From high-performance PET cup production with the new SPEEDFORMER KTR 6.2 Speed, smart automation, and precise in-house toolmaking to pioneering fiber, appliance, and medical solutions.

- Live demonstrations of our latest machines: SPEEDFORMER KTR 6.2 & NATUREFORMER KFT Lab

- Turnkey solutions for flexible, sustainable production

- Green, smart, responsible – this year’s K theme in action

Let’s celebrate 70 years of innovation – and shape what’s next, together.

Meet us at the K Show – Hall 3, Booth D90!

Highlights at the K Show 2025

KTR 6.2 LIVE Demo - next-gen packaging technologies

Watch the new KTR 6.2 live in action – forming PET cups with maximum efficiency and precision.

Together with our automation units, the CUPPACKER and the SPEEDSTACKER, this powerful system ensures fast, reliable cup production. A complete solution for high-output packaging lines.

Give your tooling a performance boost

The KMD 78.2 Power and KMD 90.1 Premium are compatible with Illig RDK and Sencorp tooling.

You benefit from reduced conversion costs, faster tool changeovers and energy-efficient performance – without compromising on precision or production speed.

Margarine tubs made from natural fiber (wet molding)

The KFT Lab is your ideal solution for developing and producing fiber-based packaging like margarine tubs in small quantities or for lab-scale testing - and will be live at the K with the brand new double dip forming method for optimal material distribution and barrier functions.

For larger production volumes, the KFT 90.1 offers a reliable and proven standard setup. Both machines process wet fiber efficiently and sustainably. With optional automation, in-house toolmaking and everything from a single source, we support you from prototyping to series production.

Margarine lids made from dry fiber

Our dry fiber solutions enable the production of sustainable packaging such as lids, trays or cups – directly formed from a roll of paper.

Using natural fibers, we shape high-quality margarine tub lids with a natural appearance and excellent strength. The result is a fiber-based alternative that meets both functional and aesthetic demands while significantly reducing environmental impact.

Medical & Pharma expertise - precise. clean. future-proof.

Our proven radio frequency and thermo contact welding systems ensure safe and efficient production of blood bags, bioprocess containers and more.

With the SOLUTIONPERFORMER and its high-precision forming, filling, sealing, we meet strict quality standards. Scalable automation supports your cleanroom production.

Sharp contours for superior cooling performance

Produce refrigerator door and inner liners with power and precision. Our SHARPFORMER series handles large formats with ease and integrates automation for streamlined production.

Durable tooling and energy-saving features make Kiefel a reliable partner for appliance manufacturers.

Digital & After Sales Services - smart service. global reach.

We keep your Kiefel machines running. The optimized Kiefel Portal gives you instant access to upgrades, spare parts, support and documentation.

Globally connected, locally available – our digital services and expert teams ensure maximum machine uptime and fast assistance when it matters most.

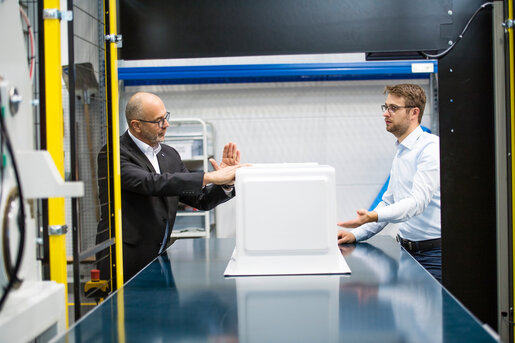

NEW: Customer Innovation Center - Polymer

Explore a space where polymer packaging ideas come to life. Test, prototype, innovate – together with our experts.