Information for suppliers

Kiefel is part of the Brückner group, based in Siegsdorf and a world leader in designing and manufacturing machines and tools for processing plastics.

Our core competencies are forming and joining technologies. Kiefel is a partner of well-known manufacturers and supplies the medical, refrigerator and packaging industries.

Kiefel is based in Freilassing, Germany, with subsidiaries in Austria, the Czech Republic and the Netherlands, branches in the USA, France, Russia, Brazil, China, Indonesia and India, as well as our sales partners in more than 60 countries.

We have a strategic and operative purchasing department. A total of 20 competent staff members handle the procurement of various products and services, divided by product groups and markets.

You are welcome to contact us in German, English, Dutch or Czech.

Delivery Address KIEFEL GmbH

KIEFEL GmbH

Klebingerstraße 5

83395 Freilassing

GERMANY

Delivery times:

Monday - Thursday 7.00 - 03.30 pm

Friday 07.00 am - 12.00 noon

Information on applying as a supplier

In order to meet the high demands of our industry, we are always on the search for high-performance business partners with a zero-error tolerance and a delivery reliability of at least 90%.

Are you a future-oriented company and do you strive for continuous optimization? We look forward to your application.

German Supply Chain Due Diligence Act

From 2024, Brückner Group is going to be subject to the German Supply Chain Due Diligence Act which contains provisions for monitoring human and environmental rights within our own company and in the supply chain. By April 2025 at the latest, we will submit the first due diligence report to the Federal Office of Economics and Export Control (BAFA) and also publish it on this page.

We already fulfil many of the legal requirements of the Supply Chain Due Diligence Act. When selecting suppliers and business partners, for instance, we attach great importance to ensuring that they act in accordance with our principles and in compliance with the applicable laws. Serious violations may even result in the termination of the business relationship.

Furthermore, in preparation for the requirements of the Supply Chain Due Diligence Act, we have developed a special analysis tool that serves to carry out an abstract supplier risk assessment. The analysis allows for a systematic overview of those countries and suppliers which could potentially pose the highest risks and which we should therefore pay particular attention to. The supplier’s activity sector is also taken into account here.

Kiefel Supplier Award

Our suppliers are the best!

With our regular international "Kiefel Supplier Awards", we reward outstanding performance in services.

We look for consistant excellence in the areas of quality, service and technical support. Sustainability also plays a decisive role in the supplier evaluation.

A long-term and sustainable partnership with our suppliers is important to us, which is why we honor the best suppliers with the Kiefel Supplier Award every year.

Congratulations to this year's winner of the Kiefel Supplier Award !

Information on application process

The Supplier Self-Assessment and Shopping Cart documents are below the buttons for the individual markets. Please complete these and send them to us.

You are welcome to add further information on your company by way of a presentation or similar to your message. Your application will be processed and answered promptly.

Please be aware that applications without necessary completed documents (Requirement Profile and Sample Portfolio) cannot be processed.

Our purchasing landscape & markets

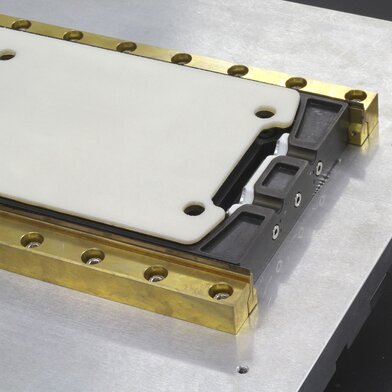

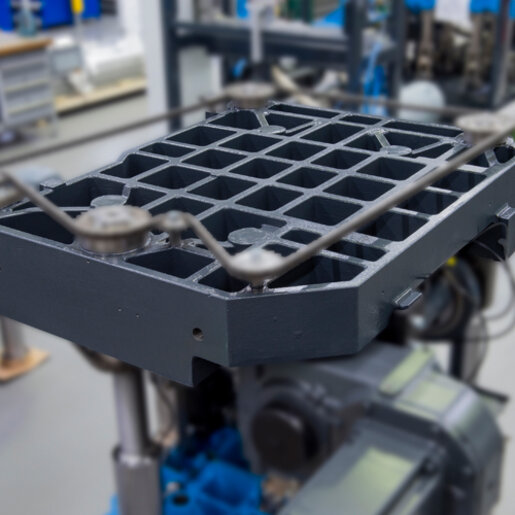

Assemblies

We purchase assemblies such as conveying elements, thermal contact welding tools and preheating units. If you are interested in producing assemblies for Kiefel, please send us the completed Requirement Profile and a short description of your company. Due to the complexity of the market, the Sample Portfolio only shows a small selection of possible assemblies.

Portfolio:

- Tools

- Punching units

- Devices

- Assembly

- Conveyor units

Processing:

- Machining

- Assembly

Materials:

- Stainless steel

- Steels, alloys

- Aluminum, non-ferrous metal

Documents:

Sheet metal

In the field of drawing-specified sheet metal parts, we are looking for suppliers with short delivery times for steel, stainless steel and aluminum sheet metal parts in different sizes and designs up to a material thickness of 15 mm. Subsequent manufacturing processes such as surface treatments, wet painting, powder coating, glass bead blasting or nickel plating are neccessary.

Portfolio:

- Covers

- Functional sheet metal

- Bent sheet metal

- 0.5 to 15 mm thickness

Processing:

- Cutting

- Edge-processing

Materials:

- Stainless steel

- Steels, alloys

- Aluminum, non-ferrous metal

Documents:

Frames

Our precision machines are built on welded steel and stainless steel frames.

Precision machining and high welding quality are therefore basic requirements for suppliers in this special market. Subsequent manufacturing processes such as surface processing, wet painting, powder coating, glass bead blasting and milling are necessary.

Portfolio:

- Serial frames

- Special frames

- Assemblies

Processing:

- Welding

- Painting

- Machining

- Assembly

Materials:

- Steels, alloys

- Stainless steel

- Aluminum, non-ferrous metal

Documents:

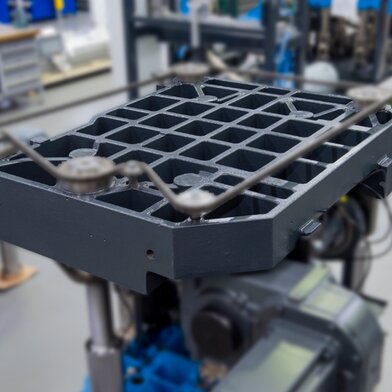

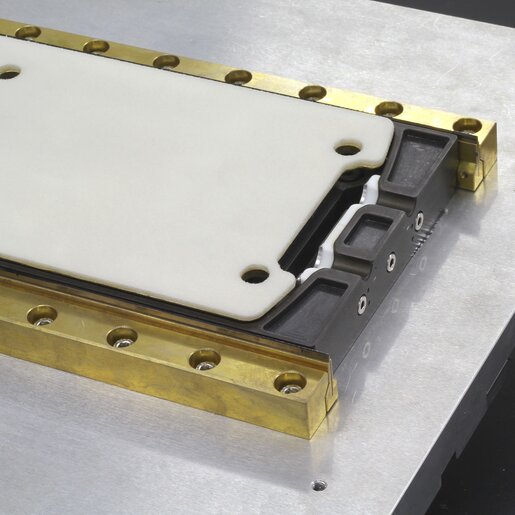

Cast parts

In this market we are looking for foundries and casting processors for tables and yokes of our successful packaging machines. The parts are standardized and require machine measurement in accordance with defined inspection protocols. Subsequent finishing processes such as coating and milling are necessary.

Portfolio:

- Press parts

- Consoles

- Functional parts

- 10 kg to 1,500 kg

- Special parts 6,000 kg

Processing:

- Casting

- Machining

Materials:

- GJS, GJL

- Alu

Documents:

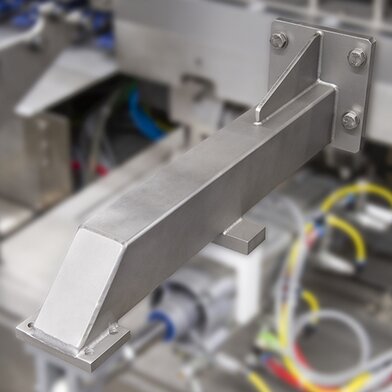

Steel construction

Steel and stainless steel welded parts literally provide the framework for our innovative systems in packaging, automotive and medical industries. High machining accuracy and welding quality are also basic requirements for supplier selection. Necessary subsequent manufacturing processes include surface processing, liquid coating, powder coating, glass bead blasting and milling.

Portfolio:

- Standard parts

- Individual parts

- Holders

- Consoles

- Assemblies

- Small parts

Processing:

- Welding, machining

Materials:

- Stainless steel

- Standard steel

- Profiles

- Sheet metal

Documents:

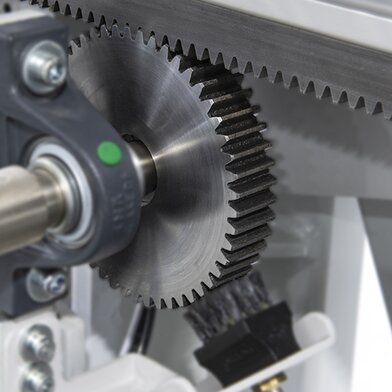

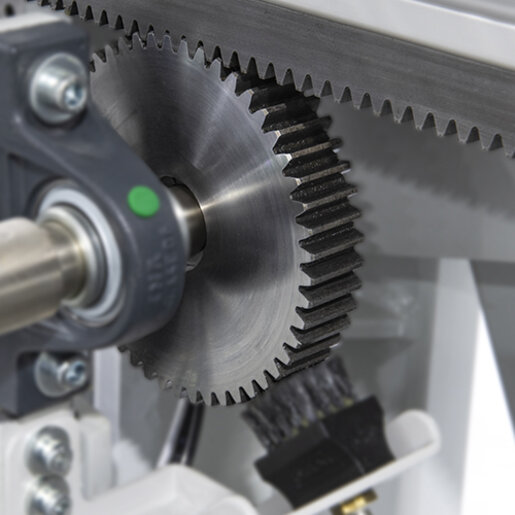

Gearing

Precise gears and toothed racks are significant core elements in the stations of our systems.

Precise manufacturing and surface finishing are among our suppliers' elementary competencies.

Portfolio:

- Gears

- Toothed racks

- Round racks

- Sprockets

- Individual parts

- Standard parts

Processing:

- Milling

- Grinding

- Hardening

Materials:

- Steel

Documents:

Machining

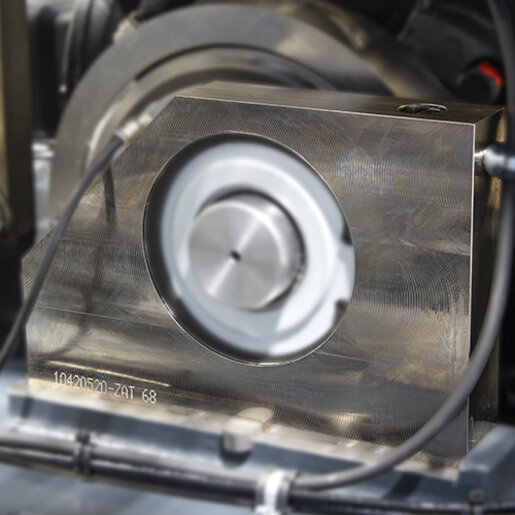

Machined workpieces made of steel, stainless steel and aluminum are a core component of KIEFEL special machines. In this market, we need suppliers for components with rotatory as well as three-axis and five-axis machining. Necessary subsequent manufacturing processes include surface processing, liquid coating, powder coating, glass bead blasting and nickel plating.

Portfolio:

- Consoles, lids

- Shafts, columns

- Special parts

- Contoured parts

- Tools

Processing:

- Turning

- Milling

- Eroding

Materials:

- Stainless steel

- Aluminum, non-ferrous metal

- Steels, alloys

- Plastics

Documents:

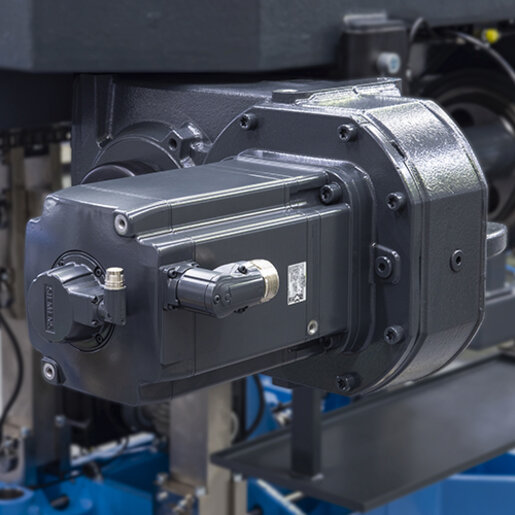

Purchased parts and raw material

A broad portfolio of parts purchased from third parties in drive technologies, industrial elements, electrical and pneumatic domains are completing the purchasing landscape for our automated systems. We primarily seek raw material suppliers for our business units. Due to the wide range of these products in our markets we do not need a Requirement Profile nor a Sample Portfolio.

Portfolio:

- Drives, pumps

- Hydraulics, pneumatics

- Cables, sensors

- Bearings

- Chains

- Seals

- Industrial products

Materials:

- Stainless steel

- Steels, alloys

- Aluminum

Documents: