Explore the Kiefel Medical & Pharma world

Reliable partner for innovative solutions in the medical and pharmaceutical industry

The medical and pharmaceutical sector demand the highest standards. Kiefel's systems for producing pharmaceutical and medical specialty bags and special application units guarantee high-quality products in these important sectors.

Costs, physical requirements, ecological aspects - a multitude of factors must be taken into consideration when selecting a suitable film material. Whichever you may opt for, Kiefel, the leader in high-frequency and thermo-contact welding is always your partner.

Kiefel customers get reliable solutions that ensure success in the market and steadiness. Our solutions mean dependability for your projects.

Medical, Pharma, Bioprocess

Bags for Infusion, Nutrition, Drug Delivery, Dialysis

Single, double and multi-chamber bags

Kiefel systems are used successfully worldwide for the production and filling of intravenous (IV) solution bags, total parenteral nutrition bags (TPN bags), dialysis and peritoneal dialysis (CAPD bags), and other specialty bags like drug delivery.

Over 5 billion bags are produced annually on machines designed and built by Kiefel.

Whether you opt for non-PVC, PVC or EVA as the bag material, with a tube or port connection component; we have the right welding and production technology. Our decades of experience in thermo-contact (TC), high frequency / radio frequency (HF/RF) welding and forming as well as filling complete our portfolio for the production of specialty single, double and multi-chamber bags used in the medical and pharmaceutical field.

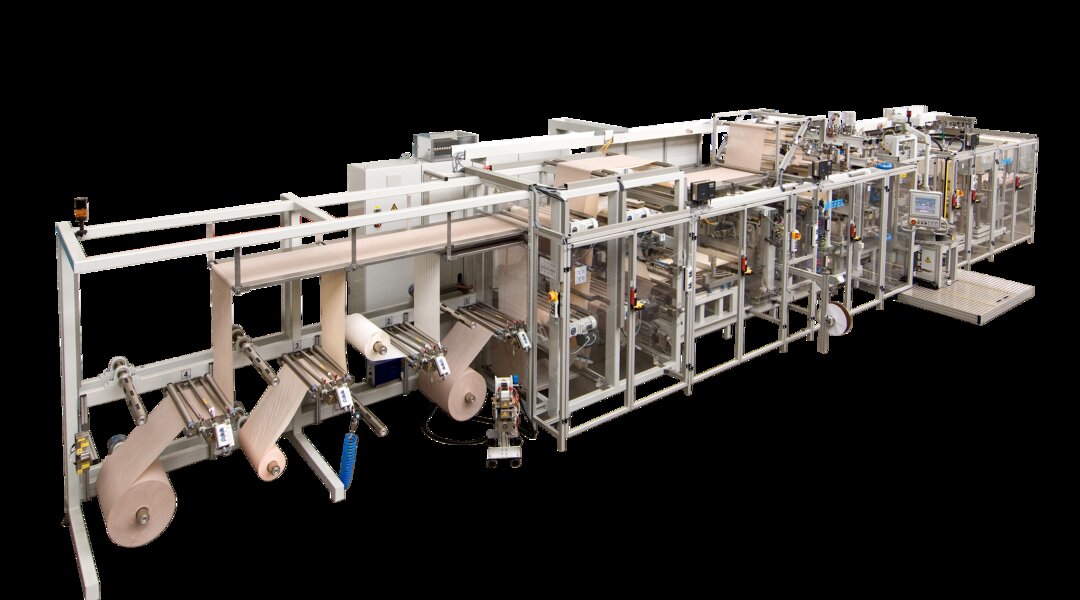

Kiefel Form Fill Seal (FFS) solutions allow the processing and production steps to be combined and integrated within a single system: bag production, bag filling, bag sealing.

Your Kiefel Benefits:

- High production rates and optimal product quality

- Optimized footprint with highest output per m² of cleanroom space

- Wide article variety and high flexibility on the same machine

- Sustainable and cost saving: potential for up to 40% film thickness saving (with SOLUTIONPERFORMER)

- Reduced particulate matter generation

- Highest bag quality through special welding steps and film and component treatment (thermo-contact welding)

- Highest welding precision and welding quality available on the market through smart welding force control

- Protection of tooling by ultra-fast arc suppression system (high frequency welding)

- Highest-precision tool design

- Quick & easy welding tool change mechanism for fast change-over and less downtime

- Control systems for quality assurance and reject part management

- Self-diagnosis system for highest user friendliness

- Machines designed for efficient maintenance and easy operator access

- Innovative crossfield-welding technology (high frequency welding)

Blood & Plasma Bags, Blood Filters

The need of any kind of blood product is high and shelf life is limited; which makes it crucial that not a single drop is lost.

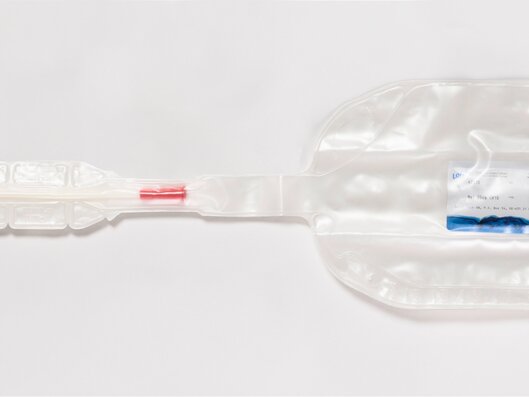

We have the right production solutions for medical bags for blood transfusion, blood plasma, platelet, red blood cells, cord blood, stem cells or other special separations and applications.

These products can be welded reliably by high frequency technology, whether they are made of PVC or EVA.

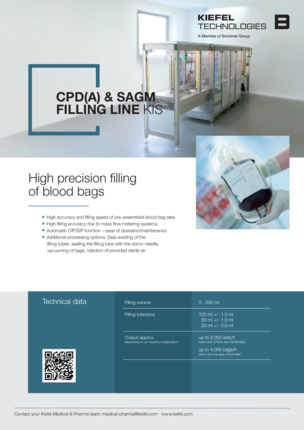

We attach great importance to the fulfillment and monitoring of the highest quality criteria when it comes to the manufacture of sensitive blood bags and blood separation products, as well as to the filling of blood bags with CPD and SAGM solutions.

Our innovative and sustainable solutions allow you to:

- profit from the highest efficiency and quality in production,

- maximize your output per square meter of clean room, and

- operate machines with the longest machine lifetime and best-in-class automation.

Every year, over 600 million blood-related bags, separation and filtration products are produced on Kiefel machines around the world.

Blood Bags & Separation Products

As an experienced market leader, we are your reliable and competent partner for the entire range of blood bags and separation or filtration products: whether your bag is made of PVC or EVA materials, demands sampling bags, top and/or bottom connections, or special separation and storage designs.

Your Kiefel Benefits:

- High production rates and optimal product quality

- Optimized footprint with the highest output per m² of cleanroom space

- Wide article variety and high flexibility on the same machine

- Reduced particulate matter generation

- Most accurate welding process, the highest available welding precision and welding quality through smart welding force control

- Protection of tooling by ultra-fast arc suppression system

- Quick and easy welding tool change mechanism

- Automatic film web control

- Highest-precision tool design

- Control systems for quality assurance and reject part management

- Self-diagnosis system for highest user-friendliness

- Machines designed for efficient maintenance and easy operator access

- Innovative crossfield-welding technology

Leukoreduction Blood filter

Kiefel has state-of-the-art, flexible inline and tray machine concepts for the manufacture of blood filters. These solutions together with our years of experience in the medical and pharmaceutical field as well as in high frequency welding, allow us to deliver leukoreduction blood filter products produced in large quantities and complying with the highest product quality standards.

Your Kiefel Benefits:

- High production rates and optimal product quality

- Optimized footprint with the highest output per m² of cleanroom space

- Reduced particulate matter generation

- Most accurate welding process, the highest welding precision and welding quality available on the market through smart welding force control

- Protection of tooling by ultra-fast arc suppression system

- Highest-precision tool design

- Quick and easy welding tool change mechanism for fast change-over and less downtime

- Control systems for quality assurance and reject part management

- Self-diagnosis system for highest user friendliness

- Machines designed for efficient maintenance and easy operator access

Drainage & Urine Bags

Depending on the film material and components used, our specialists recommend either thermo-contact or high frequency welding technology for the production of urine bags, urine catheter bags or drainage bags. In accordance with the bag design requirements, various components and valves can be welded between the layers of material.

Your Kiefel Benefits:

- High production rates and optimal product quality

- Optimized footprint with highest output per m² of cleanroom space

- Wide article variety and high flexibility on the same machine

- Highest precision tool design

- Protection of tooling by ultra-fast arc suppression system (high frequency welding)

- Quick & easy welding tool change mechanism for fast change-over and less downtime

- Control systems for quality assurance and reject part management

- Self-diagnosis system for highest user friendliness

- Machines designed for efficient maintenance and easy operator access

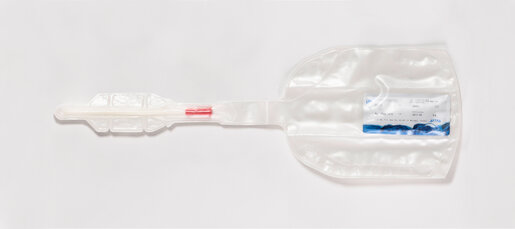

Urine Catheter Products

Catheters have become essential for patient care. As your partner, we design and build your individual system solution for the production of urine catheter products.

We offer a wide range of solutions for the manufacturing of various urine catheter products; from processing the pre-fabricated catheter, welding the urine receiving bag, to manufacturing and integrating in-bag fluid dispensers into the receptacle, or applying lubricant along the catheter.

Millions of urine catheter products are manufactured annually on machines developed and built by Kiefel.

Your Kiefel Benefits:

- High production rates and optimal product quality

- Optimized footprint with highest output per m² of cleanroom space

- Reduced particulate matter generation

- Most accurate welding process, the highest welding precision and welding quality through smart welding force control

- Highest-precision tool design

- Quick & easy welding tool change mechanism for fast change-over and less downtime

- Control systems for quality assurance and reject part management

- Self-diagnosis system for highest user friendliness

- Machines designed for efficient maintenance and easy operator access

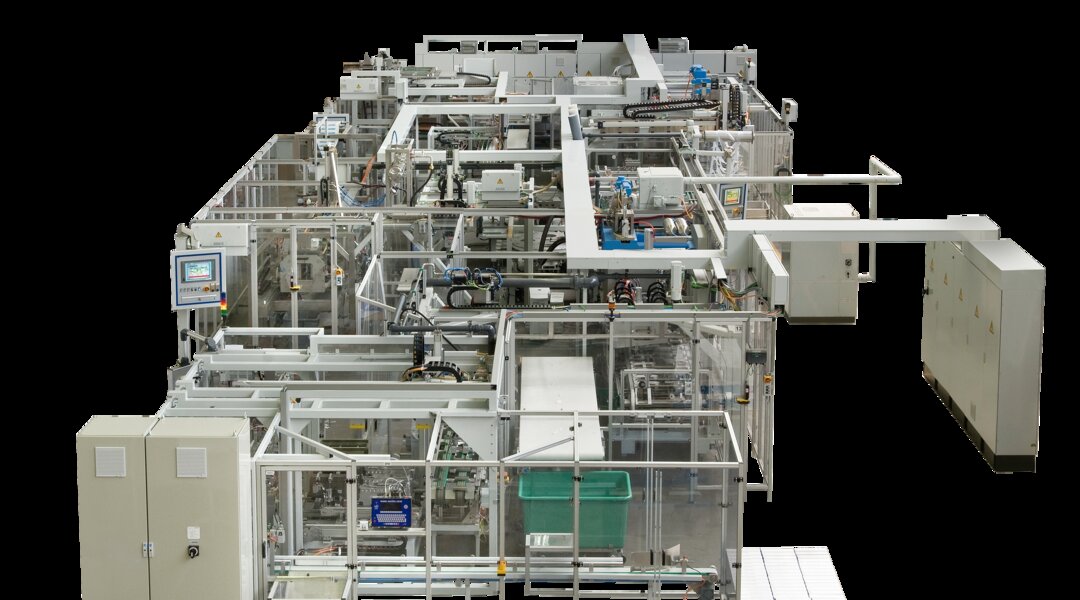

Ostomy Pouches

Colostomy bags, ileostomy bags, urostomy bags

We understand the sensitivity of issues relating to ostomy bags for the user. They must be comfortable and inconspicuous; they must be odor-free and never leak. With this in mind, we manufacture our systems to produce ostomy bags with the utmost focus on quality, comfort and reliability.

Every year, over 300 million ostomy bags are produced on Kiefel machines around the world.

Our know-how covers all areas of ostomy pouch production: closed or open bags, with e.g. inspection windows, activated charcoal filters for venting and odor prevention, soft adhesive adapters or hard plastic flanges, different materials and film layers, or label applications.

Our fully automated systems and our semi-automatic machines with manual component feeding are customized to your requirements.

Your Kiefel Benefits:

- High production rates and optimal product quality

- Optimized footprint with highest output per m² of cleanroom space

- Outstanding article variety and flexibility on the same machine

- Most accurate welding process, the highest welding precision and welding quality available on the market through smart welding force control

- Maximum precision tool design

- Quick & easy welding tool change mechanism for fast change-over and less downtime

- Control systems for quality assurance and reject part management

- Self-diagnosis system for highest user friendliness

- Machines designed for efficient maintenance and easy operator access