KIEFEL presents Cup Forming Machine KTR 6L SPEED at NPE 2012

04 May 2012

Power plus, with forming area of up to 780 x 560 mm. The THERMORUNNER KTR 6 L SPEED is the top-of-the-range model of the KIEFEL cup forming series.

KIEFEL will present its Thermorunner KTR 6 L SPEED at NPE 2012 in Orlando with a high-speed demonstration producing drinking cups from PP material using a 50up cup-tool.

Yogurt cups, drinking cups, cups for use with snap-on lids or plant-pots, KIEFEL’s Thermorunner KTR 6 L SPEED Cup Forming Machine combines intelligent technology, perfect quality and optimum production rates with minimum costs.

A perfect integration of the innovative Inline Stacking System KIST 78/56 with vertical stacking, also developed by KIEFEL, makes the KTR 6 L a reliable partner with a fascinating speed of all operation sequences. As each customer’s needs are different, the KTR 6 L is designed on a modular basis. It can then be expanded with downstream equipment for complete packaging solutions.

Packaging Industry: High-performance pressure forming machines

The SPEEDFORMER KMD Series set the standard for automatic pressure forming machines. Tried-and-tested technology for the cost-efficient mass production of packaging items made of plastic: the KIEFEL SPEEDFORMER KMD Automatic Pressure Forming Machines.

The Sophisticated machinery design, the innovative drive technology and the SIMOTION Control System of Siemens ensure faster and more precise movements of the SPEEDFORMER machines.

Typical applications of the KMD SPEEDFORMER include trays and containers, hinged packaging, blister packs, tub lids and sorting elements.

Medical Technology: Whether you are looking for thermo-contact or radio-frequency welding, flat or tubular film material, KIEFEL can provide manufacturing solutions for infusion bags that fulfil the highest performance specifications.

Thanks to its newly-developed IV Express, welding-technology specialist KIEFEL meets the needs of the market to perfection. An innovative line for the production of IV bags with integrated filling

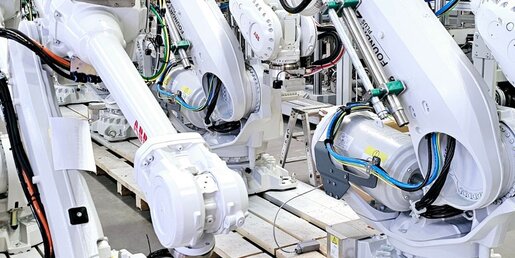

Individual solutions for the Automotive Industry: KIEFEL is one of the international market leaders wherever the processing of plastics for the automotive industry is concerned.

Working in close cooperation with our customers, we plan and provide complete solutions for the production of interior trim components, like instrument panels, door panels, consoles and covering elements, map pockets, pillar liners, sun visors

Appliance Industry: Technologies for efficient production of refrigerator inner and door liners