Stacking & Automation Solutions

for steel rule cutting machines

Increasingly shorter product life cycles, a shortage of skilled workers and the trend towards individualization require flexible stacking and automation solutions tailored to customer requirements.

We provide you with the right stacking & automation solutions for your SPEEDFORMER KMD. Count on efficient stacking solutions such as Pick & Place, A/B stacking, tip stacking or stacking up/down.

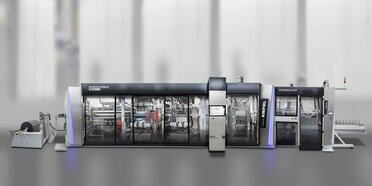

The Kiefel SPEEDAUTOMATION (KSA), which is based on a modular system, fully covers the requirement for a completely modular and therefore flexible standard automation for the KMD series, in especially for the SPEEDFORMER KMD 78.2 Speed.

The standardized automation is supplemented by customer-specific solutions such as the SPEEDPACKER (KSP) and the SPEEDPADDER (KSD).

Stacking

Pick & Place

Pick & place systems offer continuous output rates. A longer conveyor belt can serve as a buffer. The formed parts can be removed in an ergonomically convenient position.

A/B Stacking

When processing thin films and with a high degree of automation during removal and filling, A/B stacking is an economical solution. The KMD systems are perfectly designed for this purpose.

Further stacking solutions

- Tip stacking

- Stacking up

- Stacking down

Automation

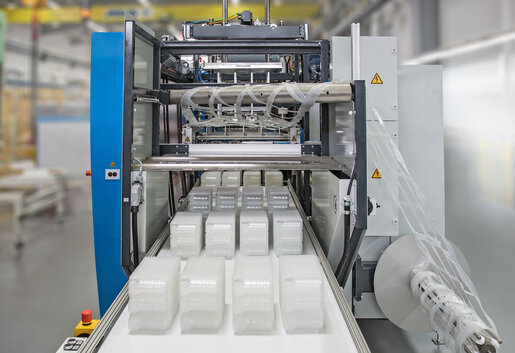

SPEEDPACKER KSP

The SPEEDPACKER is a standard automation module for SPEEDFORMER KMD series. The SPEEDPACKER includes an automated shuttle transfer of the finished formed trays. With optimum buffering of the trays, the operator can remove them at an ergonomic height.

Increase your production efficiency & benefit:

- More buffer time

- Multiple machine operation by one person

- Ergonomic & safe working hight

- Reduction of labor costs and associated costs

- Flexible use with new & existing machines as well as for machines from other manufacturers (on request)

- Optional: Gate for noise reduction

Technical highlights:

| Removal height product stack | 700 - 1,000 mm |

| Removal conveyor dimensions | approx. 1,900 x 780 mm |

| Conveyor belt speed | adjustable |

| Installation surface | appx. 3.5 x 1.9 x 3 m |

| Production speed max. | 50 cycles/min |

Intelligent interaction of material, machine and automation

Increasingly shorter product life cycles, a shortage of skilled workers and the trend towards individualization require flexible automation solutions tailored to customer requirements. The answer to this is the new Kiefel SPEEDAUTOMATION (KSA), which is based on a modular system. In addition to customer-specific automation solutions, the KSA offers completely modular and therefore flexible standard automation for the KMD series, especially for the SPEEDFORMER KMD 78.2 Speed.

Perfect match of the KSA modules to the KMD series

The KSA is optimally matched to the KMD series and can be integrated into existing systems as well as into new machines. This allows the production of packaging with various modules to be automated and modernized.

A KSA module forms stacks from partial stacks, e.g. of food trays. Another module is the carton erecting and closing unit. It removes cartons from a box magazine, erects them, and, if necessary, inserts a protective bag for hygienic packaging of the products. The stacked packaging is automatically inserted into these. As soon as the carton is full, the bag and carton can also be automatically closed and transported onwards as required. The KSA range also includes an automatic labeling unit.

The palletizing unit consists of two palletizing stations. This makes it possible to palletize in one station while the other is being emptied. If the products are not to be packed in cartons, the sleeving module can be used. Here, one or more stacks are packed and shrink-wrapped.

Kiefel Driving Digital – KMI 2.0

Intuitive machine operation

Dive into the world of thermoforming 2.0 with the new machine interface generation KMI 2.0! The intuitive machine operation simplifies your thermoforming processes and supports you in many ways:

- short training time

- fast recipe optimization

- fast error handling

- guided maintenance system